WEG will supply its first MVW3000 medium-voltage variable speed drive manufactured at its plant in Mexico. The equipment will be delivered to Beraterín, the company that acted as the equipment supplier for the project, for a power generation plant located in Cuautla, Morelos state. The drive will be used in a combined cycle power plant, where it will operate in the pumping system for treated wastewater, which is essential for the plant’s water-steam process.

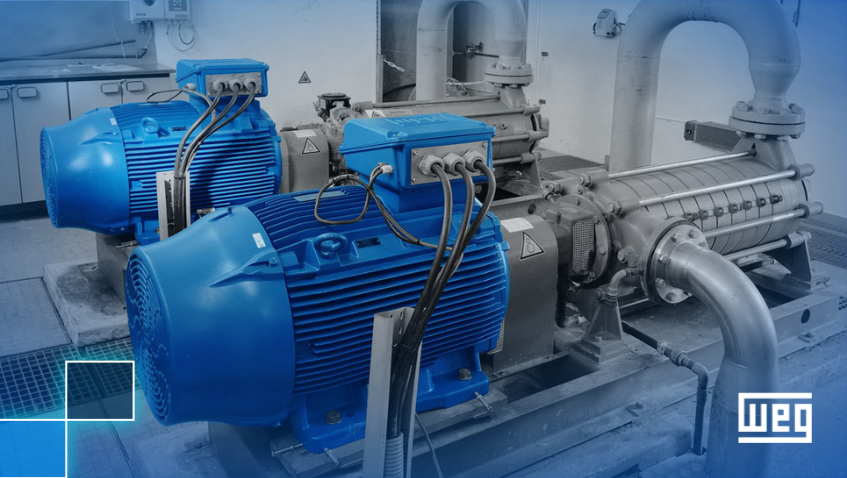

Recognized in the market for offering specialized automation solutions, Beraterín will be responsible for managing the supply and installation of the equipment, meeting the technical requirements demanded by the plant. The system was designed to control two 1,250 HP pumps, operating alternately (one in service and the other on standby), with a voltage of 4,160 V. The MVW3000 will ensure precise regulation of the water flow from the wastewater treatment plant (WWTP) to the demineralized water systems, providing greater process stability and helping preserve the plant’s hydraulic components.

This is the first MVW3000 drive produced in the country, representing a milestone for both the company and the local energy sector. The supplied model features multilevel inverter technology with IGBTs in a CHB (Cascaded H-Bridge) topology, high-reliability and easy-to-install power cells, redundant forced-air cooling, and communication compatibility with industrial protocols such as Modbus, Profibus, and Ethernet/IP, among others. It also offers a high-power factor (above 0.95 without external correction) and low harmonic distortion in compliance with IEEE 519, ensuring efficient performance aligned with application requirements. The system also includes an MMI with a touchscreen for local monitoring and operation, as well as remote connectivity through integration with SCADA (Supervisory Control and Data Acquisition), DCS (Distributed Control System), among others.

The supply is part of a pilot project focused on wastewater control, with the potential to be replicated in other plants managed by the energy supply company.

For the customer, the main benefits include greater system reliability, reduced mechanical wear on control valves, extended component lifespan, and improved energy efficiency of the process. For WEG, this is a reference project that reinforces its local manufacturing and supply capability with national technical support and opens new opportunities in Mexico’s power generation sector.